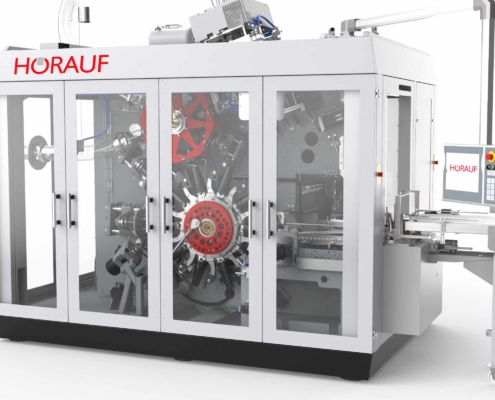

The HÖRAUF BMI/BIW machines for the production of double-walled beverage and packaging cups with paper outer sleeve

up to 180 cups per minute (BMI 100)

up to 160 cups per minute (BMI 100 SUPER)

BMI 100 series

For the production of the classic insulating cup.

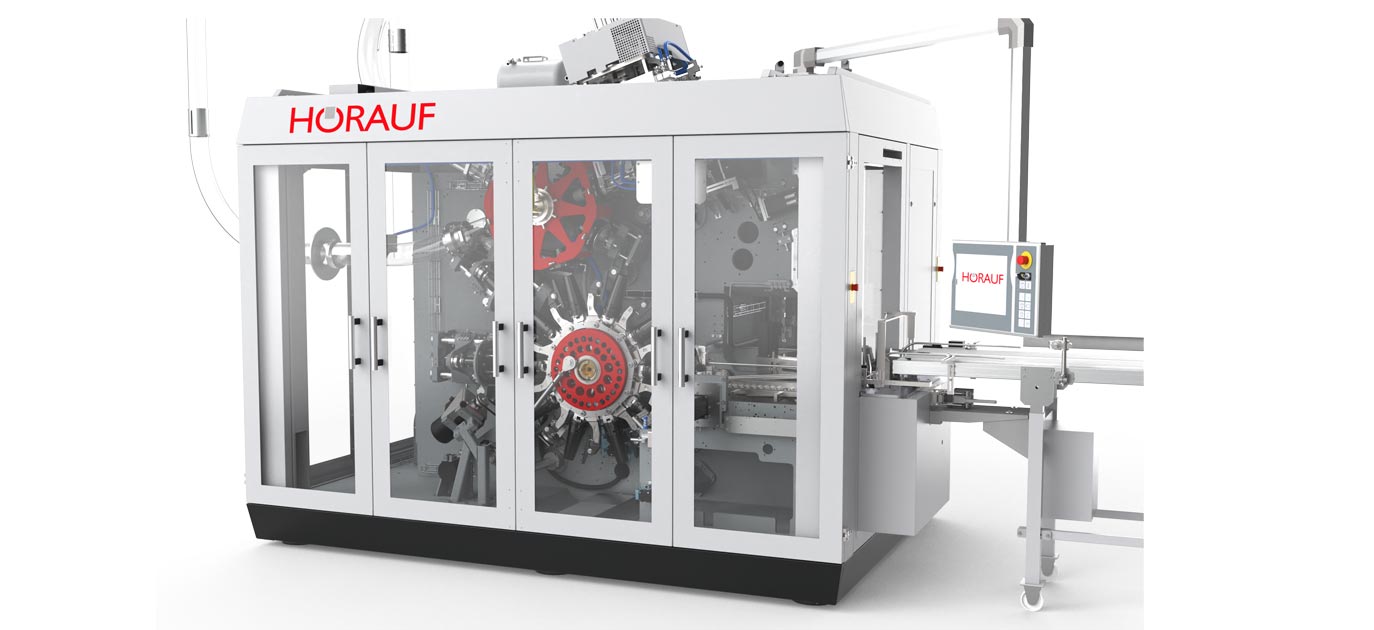

BMI 100

The BMI 100 series manufactures an outer sleeve into which the prefabricated inner cup is inserted in the next step. By means of hotmelt or cold glue (pasta cup), the two elements are joined.

Possible cup variants (in combination with BMP machine) :

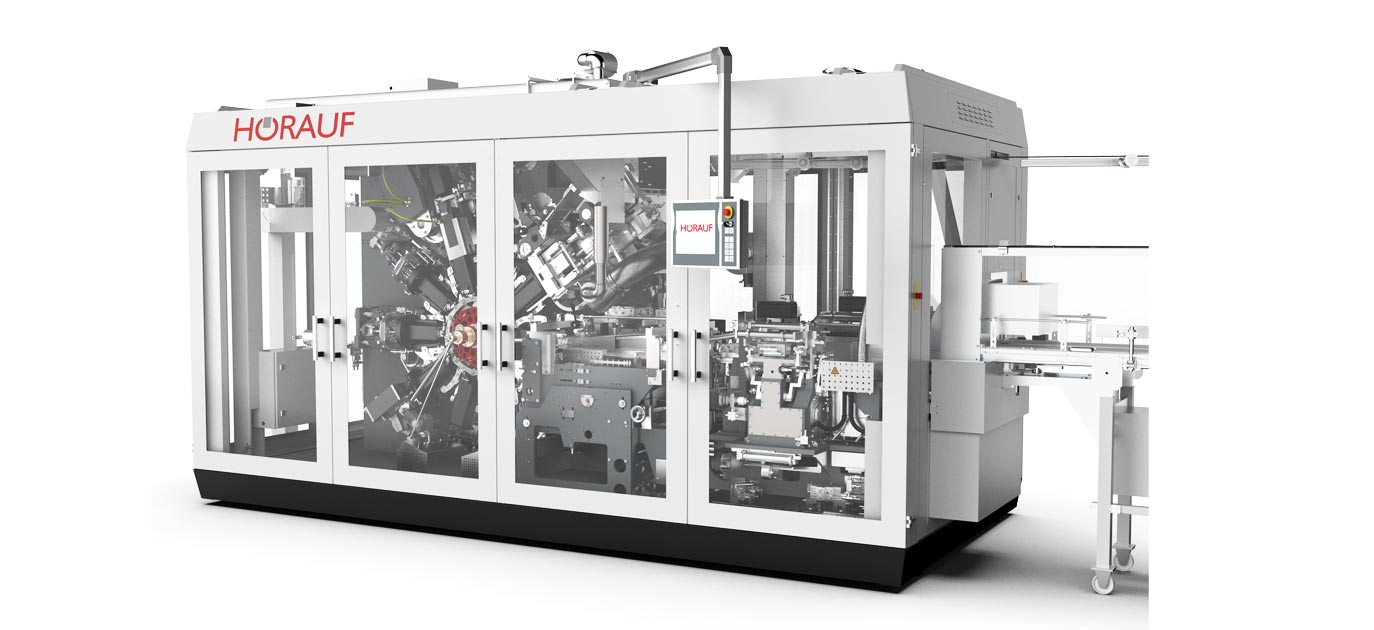

BMI 100 SUPER

The BMI 100 Super can be used to produce large-format insulated cups, e.g. for instant noodle soups and similar applications.

Possible cup variations:

Various units such as roll punch, vacuum pump, cooling unit, etc. are optionally available – depending on requirements. (Fig. similar – subject to technical changes)

The HÖRAUF BMI outer sleeve machines for the production of double-walled beverage cups

with outstanding insulation properties.

up to 230 cups per minute

BMI 300

The BMI 300 series ideal for coffee cups.

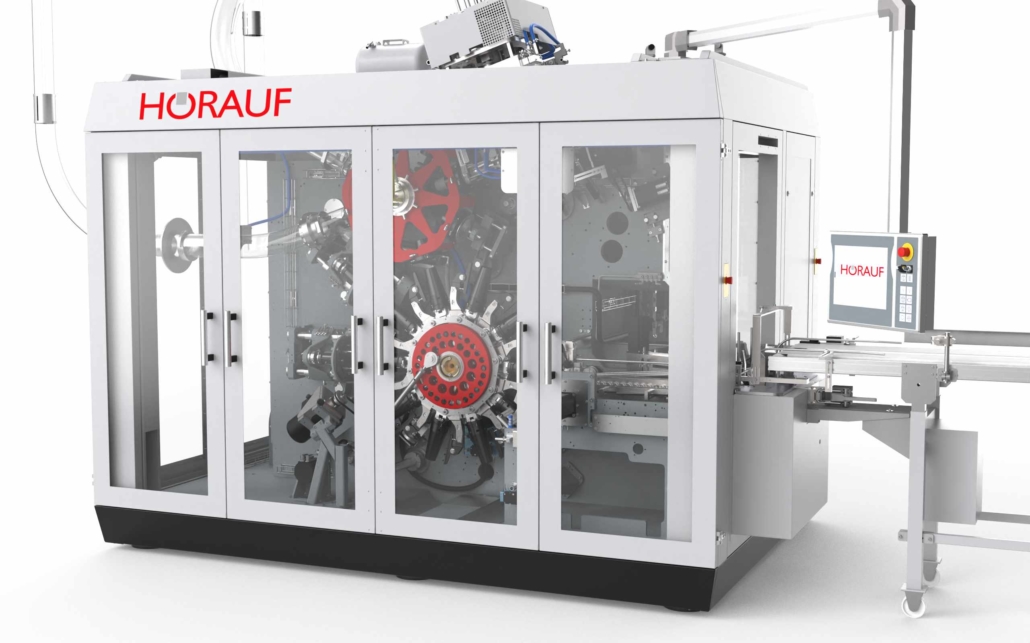

BMI 300

The fast BMI 300. In combination with a BMP machine, it produces air-insulated double-walled coffee cups such as the ” CALYX® ” cup. Suitable also for large formats with high output.

Possible cup variations:

Various units such as roll punch, vacuum pump, cooling unit, etc. are optionally available – depending on requirements. (Fig. similar – subject to technical changes)

The BIW outer sleeve machines for the production of double-walled packaging cups with outer sleeve (paper) and inner plastic cup

up to 230 cups per minute

BIW 1 / 2

The BIW series for outer sleeves with structure.

BIW 1

The BIW series wraps a segment around a prefabricated round plastic inner cup. This combines the stability of the paper sleeve and the excellent print image with the advantages of a thin-walled plastic cup.

Possible cup variations:

BIW 2

This machine offers the possibility to provide also non-round plastic cups with a paper sleeve. Optionally also with a paper bottom which provides additional stability.

Possible cup variations:

BIW 100

The BIW series wraps a segment around a prefabricated inner cup (BMP series). This technique is particularly suitable for insulating cups with an embossed outer sleeve.

Possible cup variations:

Optionally, various units such as vacuum pump, cooling unit, etc. are available – depending on requirements. (Fig. similar – subject to technical changes)